Adjustable Kits

Spring Kits

Uprated Kits

Lever Arm Conversion

Bespoke Shocks

Other Information

In order to view PDF Files you have to download and install Acrobat Reader:

![]()

SPAX SUSPENSION - Quality Guaranteed

Performance dampers, manufactured to the most stringent standards

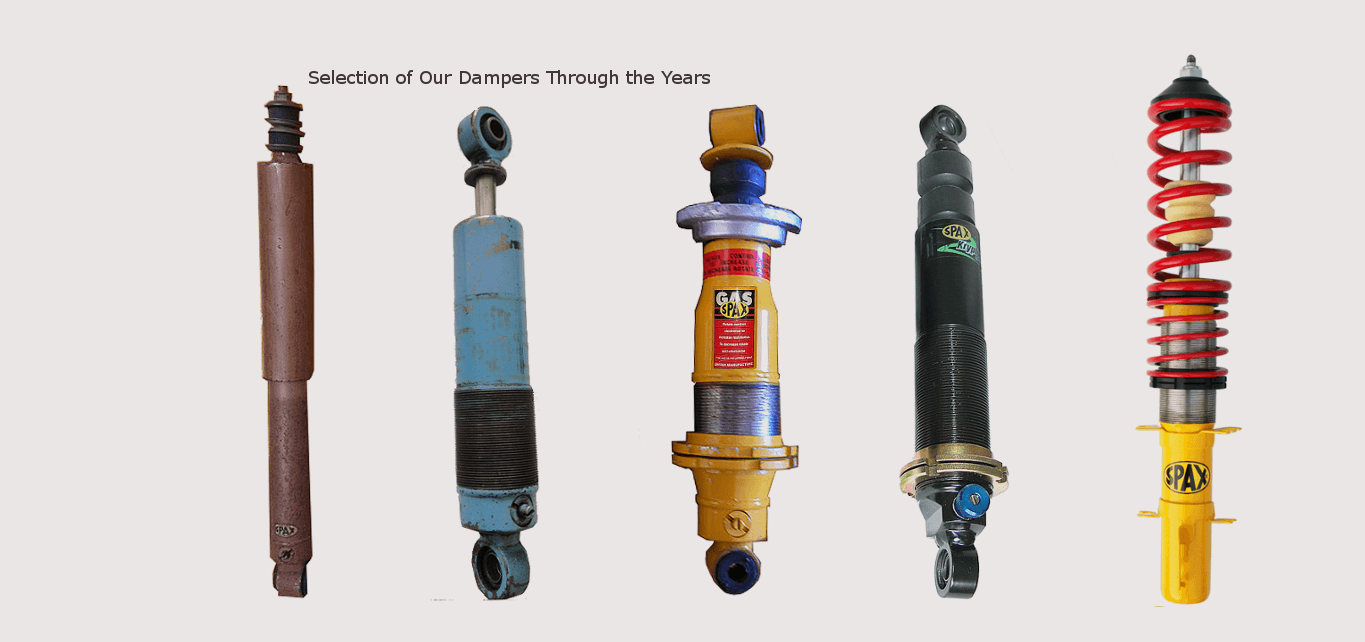

Spax supply premium on-car adjustable shock absorbers and matched suspension kits, supplying OEM clients, Motorsport Teams, Enthusiasts, Garages, Restoration Shops and Dealers - on time and at a consistent price / quality threshold which has cemented many long term relationships. A privately owned company, we have gone from strength to strength, Spax is regularly used by drivers and race teams who demand quality, durability and reliability at reasonable prices.

We have been in business for over 60 years, and as a modern, innovative, company Spax patented adjustable shock absorbers and have hand made quality products since the company was founded in London. We are proud of our racing pedigree, from very early on in our history our products were chosen by drivers who craved the best set-up on their cars. Race teams demand top quality and reliabilty and Spax have always delivered, with the added bonus that Spax dampers are adjustable - they can be tuned to prevailing conditions and driving style putting our customers in pole position. The years of development witnessed in our racing heritage has carried over to benefit the millions of Spax customers who use our products on their road cars every day.

Our Bicester factory, with modern systems had investment close to £1 million, transforming the production facility into a world class manufacturing unit, providing flexibility and customer service which has seen our export market share grow significantly. All products are 100% tested, epoxy powder coated and oven baked to ensure customers get guaranteed quality, absolute performance and long life.

Our range includes catalogued items proven to upgrade suspension performance in a huge variety of cars, old and new. Choose from three classes of suspension upgrade kits, lowering spring kits and dampers. To learn more about our product range please visit our company website www.spaxperformance.com

Manufacturing to German TüV Standards

A JOURNEY FROM ISO9000 TO TüV

Spax have always produced quality products, with an enviable reputation for innovation and price / performance, and, as a reputable car parts manufacturer, to demonstrate the standard of production, we had ISO9000 manuals and procedures.

In 1999, with new owners, a deal of investment was made in the factory, and those processes were reviewed with a view to export markets, and at that time Spax were proud to achieve TüV accrditation. The German TüV (Technischer Überwachungsverein) agency applies stringent regulation and standards testing for manufacturered products and Spax is certified for the "development and production of suspension components" demonstrating compliance with National and International regulations to ensure our dampers are built to the highest possible standards.

Unlike some of our competitors we have our own factory, in Bicester, manufacturing to exacting TuV standards. We don't sub-contract our production from overseas and can offer industry leading one week production leadtimes. Quality inspectors monitor every stage of the production process. Having TüV guarantees that Spax dampers are manufactured to meticulous standards and ensures we can export our products readily as posession of TüV accreditation is seen as a benchmark standard worldwide.

A car supplied into Germany and Austria must, in common with all EU countries, possess EC Type Approval to be registered. After three years cars are then subject to a combined HU (Hauptuntersuchung) Safety Inspection and AU (Abgasuntersuchung) Emissions Test which then has to be repeated every two years. The “Control” or inspection, which is similar to the British MOT Annual Safety Test, is mandatory and cars that have been examined and passed inspection are required to carry a sticker, placed on the number plate. The organisation that carries out the inspections is the TüV.

German Laws governing the condition of cars are strict, they include all EU regulations but differ in the respect that the safety test also incorporates stringent conditions regarding the provenance of any components used in the modification to the original design of vehicles. The engine, chassis and all other major components, including brakes, tyres, horn, wheel alignment, windsscreen, lights and mirrors will be checked to ensure that they are standard equipment, that they are undamaged and work correctly.

The basic rule is that if an item is mounted on the vehicle, it must function and be completely serviceable even if not essential to operation. Cars imported from outside the EU may require costly modifications to meet the German standards and it also means that if any modifications to the car are made, including fitting after-market spare parts, then both the parts and technical quality of the modification must be TüV tested to a high standard. All components fitted must have been specifically designed and tested to be suitable for the particular vehicle and the inspector can demand to see certificates to prove their authenticity.

Not all after-market components require a full TüV certificate to be fitted to a car in Germany or the other countries operating this system, however, if asked at the Inspection, the owner must be able to provide information to prove that the parts used are safe according to EU standards and also that they have been manufactured specifically to fit the make and model of the vehicle they are being used on. Should the design of the car not be compromised a testing engineer may require direct "swap-out" components, for example dampers, be proven to have been specifically manufactured for the tested vehicle, in this case they may ask for a "certificate of compliance".

If the components fitted to the vehicle significantly modify or deviate from the standard car design then the tester will require a full TuV Certificate to prove that the modified parts are safe to use, have been correctly fitted and that the exact combination of modified parts and vehicle have been tested by independent engineers with a certificate issued, for example by either Technischer Überwachungsverein (TÜV), DEKRA. Gesellschaft für Technische Überwachtung (GTÜ) or KÜS.

A suspension kit which lowers the ride height of the car, for example, will certainly be required to have been TüV inspected to ensure that the car is safe in operation following modification and the components used will be required to be proven. A full TüV Certificate will be requred to prove the combination of kit and car has been tested and approved.

TüV Certificates are only required for products exported to Germany and the other countries in Europe that follow their regulations for safety testing cars. We don't have TüV Certificates available for Spax Spring Kits or Spax VSX or PSX Suspension Kits, but we can issue "Certificates of Compliance", when requested, for our Shock Absorbers to prove that they have been specifically designed for a particular make and model of vehicle, and these certificates have the benefit of stating that our company is indeed TüV Registered and the components will have been manufactured to TüV Standards.

We do have FULL TüV CERTIFICATES for the majority of our RSX COILOVER SUSPENSION KITS - please see our catalogue and compatibility guides here to identify those RSX kits (marked as TUV) which can legally be fitted to cars in Germany and the countries which demand this regulation.

SPAX Warranty

SPAX offer a two year guarantee with all our products

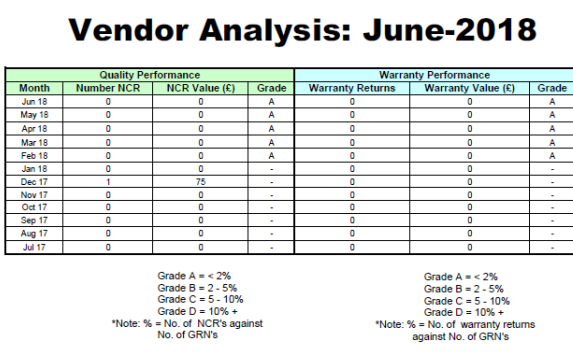

We are justifiably proud of our manufacturing quality and product reliability. As a TüV registered organisation we have audited quality control and through our work with major OEM's, and as a Tier 1 industry supplier, we have independent data provided which rates our Quality & Warranty Performance so you can be assured Spax products perform to a high standard - consistently and reliably! Our reliability rate across the board in the last two years has exceeded 99.99%.

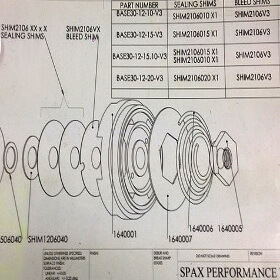

Every one of our parts is physically tested prior to dispatch from our factory, indeed each Damper we produce is individually Dyno tested before shipping to a customer, however, our products are mechanical devices and, as with every manufacturing process, we accept that on rare occasions a Spax product may well have an issue in use. The vast majority of problems associated with newly installed shock abosrbers and suspension kits can usually be traced to initial, incorrect, specification or a problem associated with fitting. We provide clear schematic diagrams with suspension kits and have a help line (+44 (0)1869 244771) for customers who wish to clarify any issue to minimise user problems, but it is possible that customers may experieince a defect and our two year warranty is there to provide peace of mind for all Spax customers.

Spare Parts

Do you need spare parts for Spax Dampers?

We have a complete inventory of spares (including bushes - please see here for a complete list of currently available bushes available from Spax) for all the products made at our Bicester factory since 1999. There are thousands of Spax dampers on cars around the world that continue to work well after the normal expected lifespan of a shock, often going stong after more than 30 years, and we're proud of their longevity but we often get asked to quote for re-builds or for individual parts for dampers built in the 1960's or 70's and, unfortunately, as we continually improve & develop our range, many components have been superceeded / upgraded in the intervening years and we're unable to supply many heritage parts, however we are proud to have detailed records of every damper we've made since Spax began and we can manufacture modern, adjustable, upgraded, dimensionally correct replacement dampers to swap-out and keep your car on the road for many more years to come!

To get a quote to purchase Spax spare parts please complete the online form here or download our Spares Part Request Form, which has clear information regarding where to locate Spax Part Numbers and Build Codes, then print it out, fill it in, and scan it or take a photo to email back to Spax.

Service & Warranty

We manufacture all our dampers in our Bicester factory and keep a large inventory of spare parts to ensure we can keep all our customers on the road. TrakSpax Racing shocks are regularly returned for annual service, and we can also rebuild and maintain our coilover dampers. There are a number of our G-dampers and our KSX units which are sealed with Pien washers, these cannot be serviced and are consumable parts. All Spax products are covered with a two year warranty and returns are processed though your original dealer or by calling 01869 244771 for a Spax Returns Number.

Please note that it is a condition of warranty that a copy of our Customer Returns Form is completed and is sent with any goods to be repaired, and when sending shock absorbers all assemblies must be stripped so that just Spax parts are returned to us.

Our full Terms & Conditions of Sale, including complete Warranty and Liability information can be found here.

Technical Support

If you need advice regarding which dampers or kits to specify for a particular vehicle, have an application or technical question or simply want to know how to get the best from your Spax products then please call us on +44 (0)1869 244771.

At Spax we provide a complete, catalogued, compatible range of Swap-Out, upgraded, adjustable, Shock Absorbers. We also supply our TrakSpax, CSX and KSX ranges of customer specified dampers for use in a variety of automobile or other applications. These dampers are often supplied for customers restoring kit cars, race, historic or rare vehicles and further details can be found here. If you have a damper that can't be identified, or you need a replacement for and can't find a close match in our self-specified range, then we can often reverse engineer shock absorbers - we charge a £100 + VAT per hour Engineering fee for this service.

The Spax brand has long been associated with some iconic car marques and to this day we remain a Tier 1 supplier to vehicle makers in the UK and abroad. If your project requires the best, adjustable, dampers then please give us a call, we'll be pleased to help.

Click Here if you want one of our Technical Sales Team to contact you.

Click Here if you want one of our Technical Sales Team to contact you.